Hits: 369 img

In humanity’s exploration of the universe and aerospace development,

silicone rubber supports aerospace technology as an "invisible

material" due to its high-temperature resistance, radiation tolerance, and

reliability. From aircraft engines to spacecraft components, it s physical limits with flexibility.

"High-Temperature Heart" of Aircraft Manufacturing

Engine Seals: Silicone rubber seals withstand extreme temperature differences from -60°C to 300°C, ensuring efficient turbocharger operation and preventing fuel leaks.

Thermal Protection Coatings: Silicone rubber coatings with ceramic particles maintain structural stability through radiative cooling, resisting aerodynamic heating during high-speed flight.

Fuel System Components: Silicone rubber and valves resist aviation fuel corrosion, with a service life far exceeding traditional rubber.

Innovation: A passenger aircraft using silicone-sealed fuel systems extended maintenance cycles to 5 years.

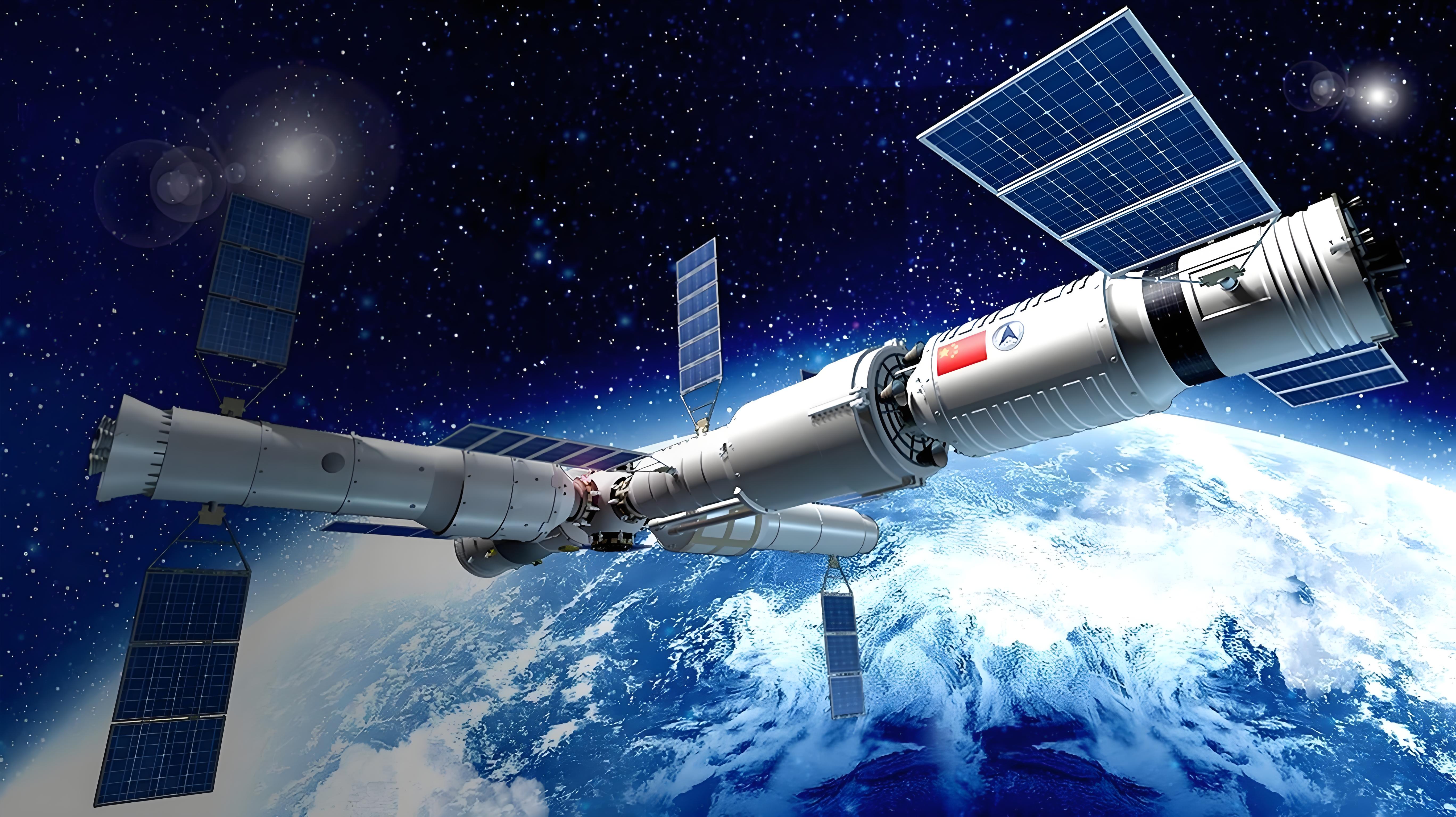

"Interstellar Armor" for Spacecraft

Satellite Thermal Control: Silicone coatings maintain internal temperature stability through radiative cooling, enduring cosmic temperature differences from -200°C to 150°C and protecting electronics.

Cabin Sealing: Silicone rubber seals retain elasticity in vacuum environments, preventing spacecraft leaks and ensuring astronaut safety.

Solar Panels: Silicone rubber spring systems enable solar panels to deploy in space, with a folded volume 1/10 of the expanded size.

Case: China’s Tiangong Space Station uses silicone sealing technology for long-term operation.

"Protective Barrier" for Avionics

Circuit Board Encapsulation: Silicone materials isolate moisture and dust, ensuring stable avionics operation in high-humidity environments.

Electromagnetic Shielding: Conductive silicone coatings reduce radar signal interference, improving navigation accuracy.

Sensor Protection: Silicone housings withstand vibration and ,ensuring accurate flight data collection.

Breakthrough: Boeing’s silicone-based electromagnetic shielding material reduces aircraft communication interference by 70%.

"Lightweight Revolution" for UAVs

Structural Adhesives: Silicone glue bonds carbon fiber composites with high strength and low weight, enhancing UAV endurance.

Propeller Coatings: Silicone anti-icing layers prevent icing, enabling UAV operation in all weather.

Shock Absorption Systems: Silicone pads reduce mechanical vibration,

extending UAV lifespan.

Conclusion

With its "high-temperature resistance, radiation resistance,

and lightweight" properties, silicone rubber is the "space

foundation" of aerospace. As commercial spaceflight advances, it may drive

safer and more efficient spacecraft.

General Purpose Grade Liquid Silicone Rubber – MY-LSR20 AB