Hits: 383 img

In the additive manufacturing revolution,

silicone rubber has emerged as a "key material" for 3D printing,

leveraging its high elasticity, heat resistance, and biocompatibility. From

medical implants to industrial components, art sculptures to smart homes, it is

reshaping manufacturing boundaries with its "flexibility."

Customization Revolution in Healthcare

Bionic Organ Printing: Silicone materials mimic the elasticity of human tissues, enabling 3D-printed artificial heart valves, tracheal stents, and personalized medical solutions.

Surgical Guides: Precision silicone-printed guides assist surgeons in planning optimal operation paths, reducing errors and shortening surgery time.

Rehabilitation Aids: Silicone-printed prosthetic liners provide comfort and fit for amputees, accelerating recovery.

Case Study: A hospital using

silicone-printed knee joint prostheses achieved a 95% patient satisfaction rate

post-surgery.

Complex Structure Master in Industrial Manufacturing

Mold Fabrication: Silicone 3D-printed molds enable rapid prototyping for intricate components in automotive and aerospace industries.

Custom Seals: Tailored silicone gaskets enhance sealing performance and durability for machinery.

High-Temperature Components: Silicone-based composites withstand up to 300°C, ensuring stable operation of industrial equipment.

Technological Breakthrough: German-developed silicone 3D printing achieves 0.1mm wall thickness precision.

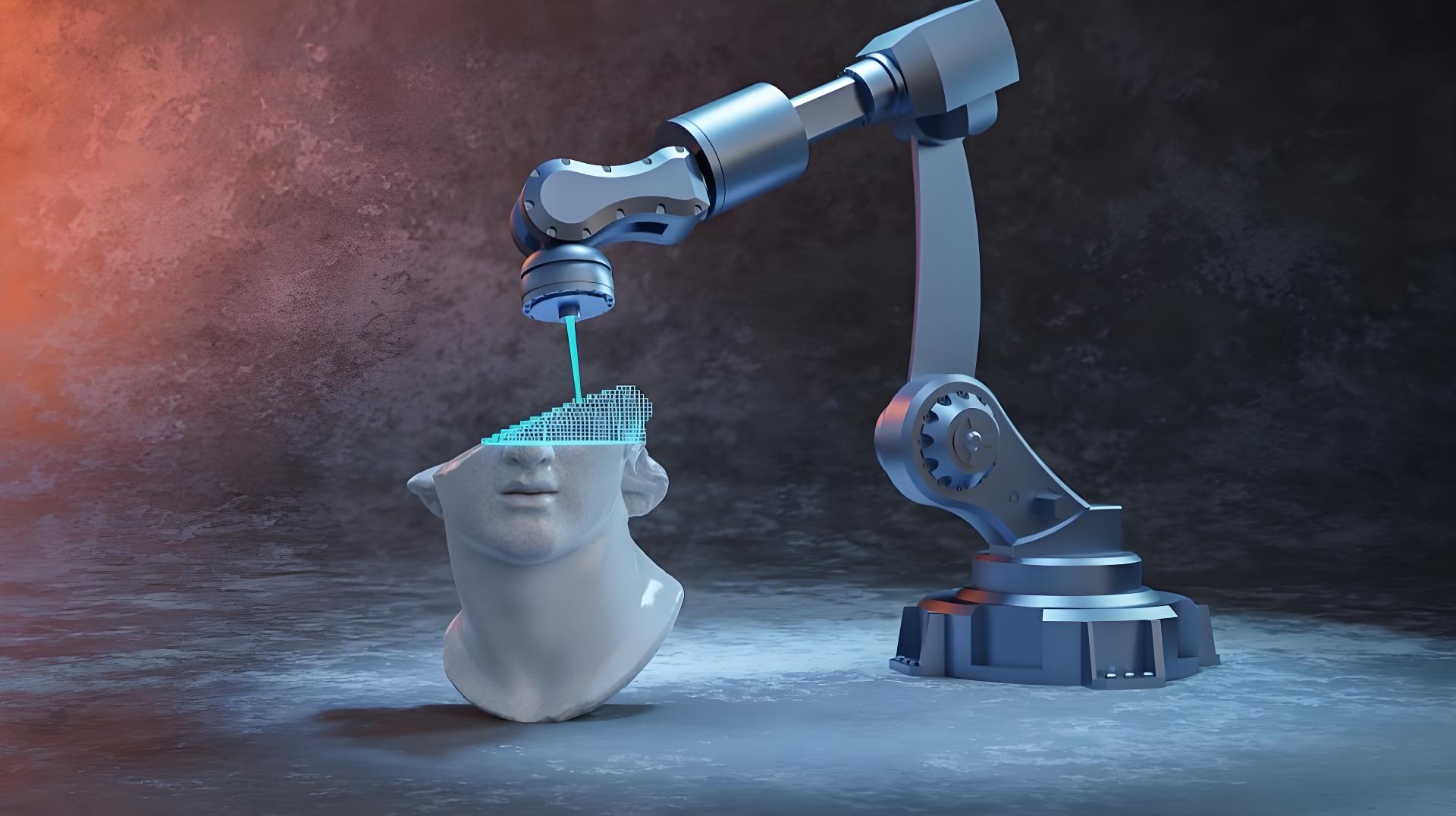

Digital Sculptor in Artistic Creation

Sculpture & Installations: Silicone supports complex printing, empowering artists to create dynamic sculptures and interactive installations.

Cultural Relic Replication: 3D scanning combined with silicone printing preserves heritage through high-precision reproductions.

Fashion Design: Lightweight silicone-printed accessories and garments blend technology with aesthetics, traditional limits.

Innovative Application: Dutch designers created temperature-responsive silicone sculptures that with heat.

Flexible Interface in Smart Homes

Intelligent Sensors: Silicone-printed pressure sensors in furniture monitor human activities and enable smart home automation.

Flexible Circuits: Conductive silicone substrates support wearable devices and smart textiles.

Modular Furniture: Silicone connectors allow quick assembly/disassembly, adapting to diverse spatial needs.

Conclusion

Silicone rubber, through the synergy of

"3D printing + flexible materials," is driving manufacturing from

standardization to customization. As printing accuracy and material performance

improve, it may become the "magic material" for universal

customization.

Fumed oil bleeding silicone rubber