High Temperature Resistance Silicone Rubber(350℃) MY HTV 329 series

Methyl Phenyl Vinyl Silicone Rubber MY 3830 SERIES

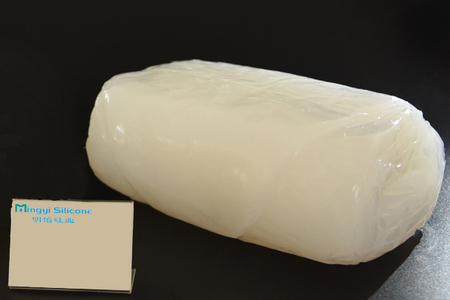

General Purpose Fumed Type silicone rubber For Molding

Low compression set precipitated silicone rubber MY HTV 333 series

Medium and high voltage insulation silicone rubber MY HTV 326 series

Description:

MY HTV 311 series products have good fluidity and mold release good,etc; Products in contact with food must be post cured at 200℃ for 4 hours.

Applications:

High-grade buttons

Miscellaneous

Special

properties:

Easy coloring

High-tensile strength

Good mold release

Good anti-yellowing property

Typical properties

|

Product |

MY HTV 31130 |

MY HTV 31140 |

MY HTV 31150 |

MY HTV 31160 |

MY HTV 31170 |

MY HTV 31180 |

|

Appearance |

Transparent |

|||||

|

William plasticity |

115 |

150 |

205 |

240 |

280 |

260 |

|

Hardness (ShoreA) |

30 |

40 |

50 |

60 |

70 |

80 |

|

Density (g/cm3) |

1.10 |

1.12 |

1.16 |

1.19 |

1.22 |

1.23 |

|

Tensile strength (Mpa) |

7 |

8.5 |

8.5 |

8.5 |

7.5 |

7.5 |

|

Elongation (%) |

700 |

550 |

450 |

400 |

300 |

200 |

|

Tear strength (KN/m) |

15 |

19 |

20 |

19 |

19 |

19 |

Remark:

1.The above data obtained from testing by using 1.0% of peroxide (DBPMH) in pressurized solidification for 5 minutes at 175 ℃ to make a 2 mm thickness specimen.

2.The above data is not for specification customized, before make this product specification, please contact sales person.

Packing&Storage

Packing:20KG/carton.

Storage:When the product is stored unopened at room temperature, the shelf life of the product is 1 year from the date of production,It is recommended to use it up within 3 months. If it exceeds 3 months, the mixing time of the product need to be extended.

*Store in a dry and cool place, avoid direct sunlight.

*Storage beyond shelf life does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.